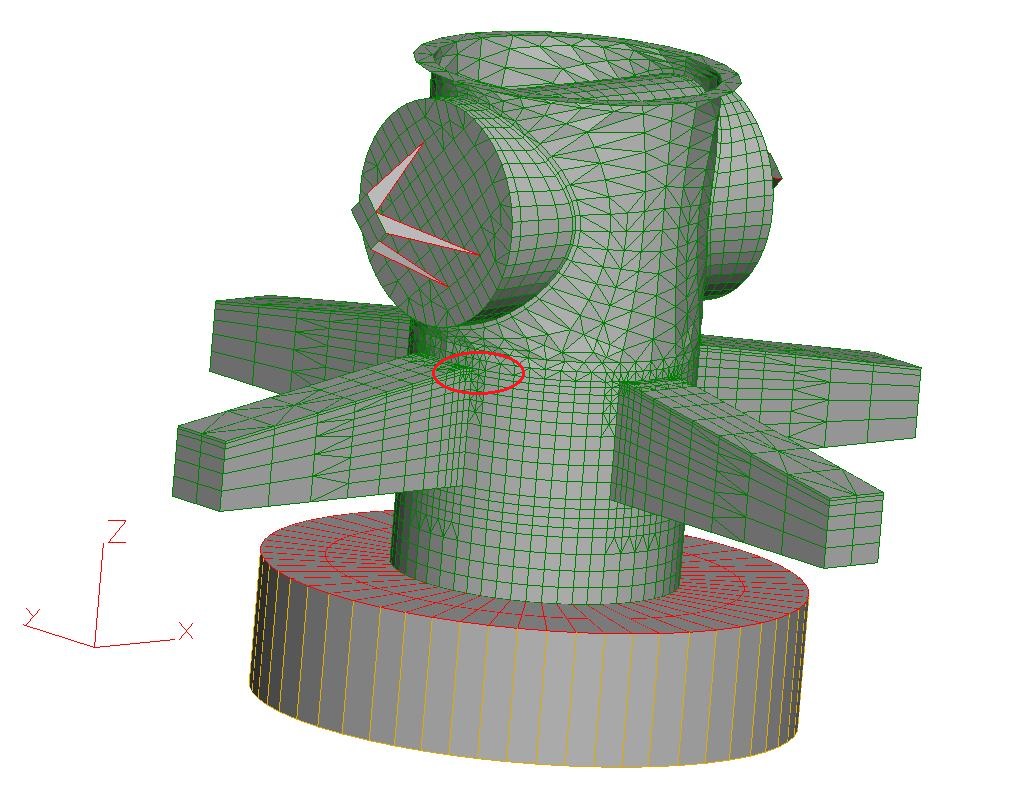

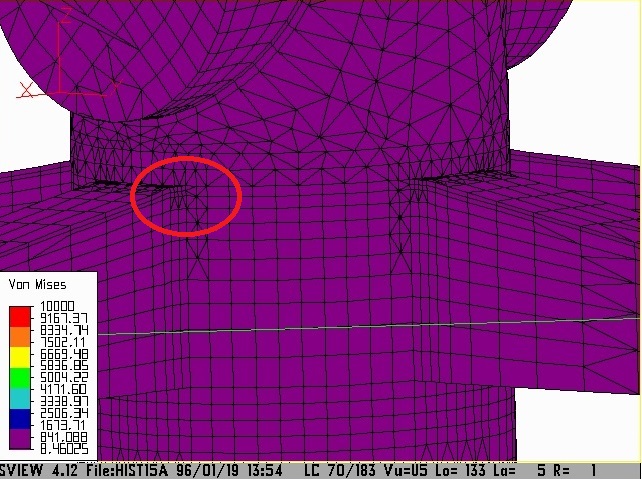

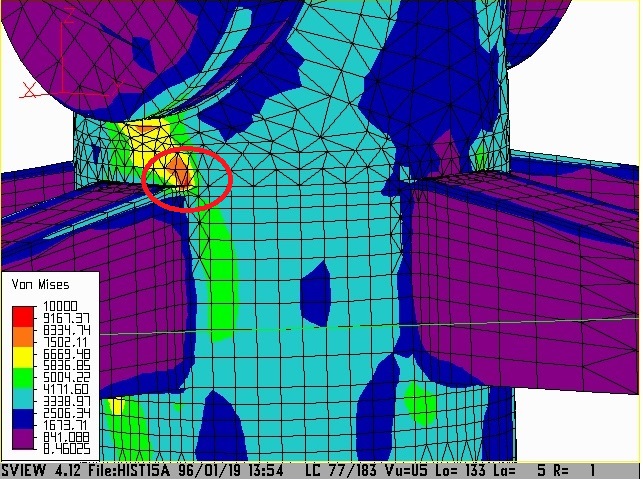

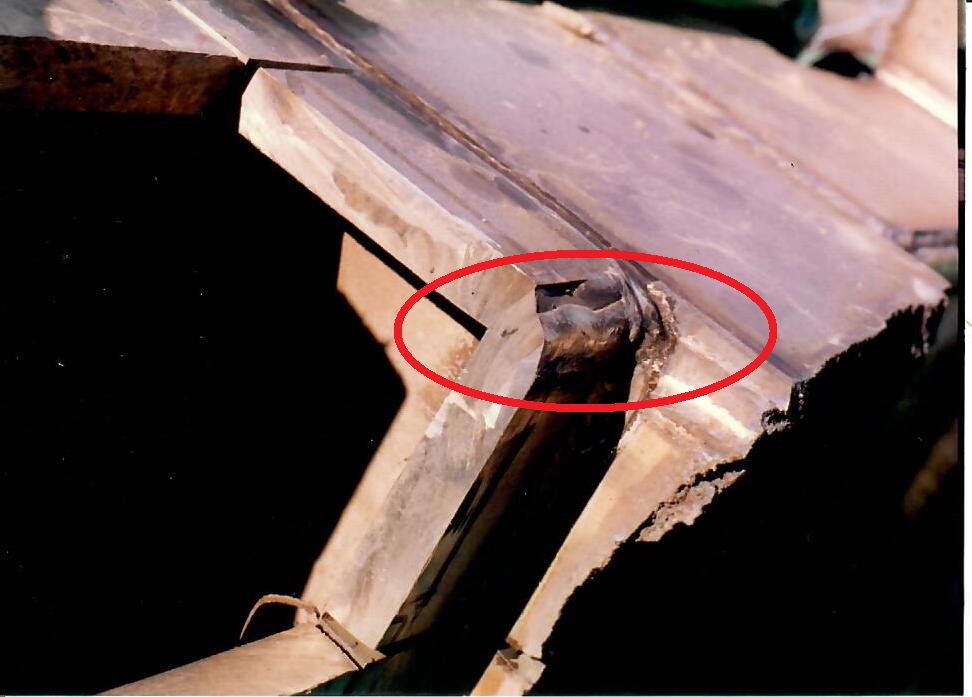

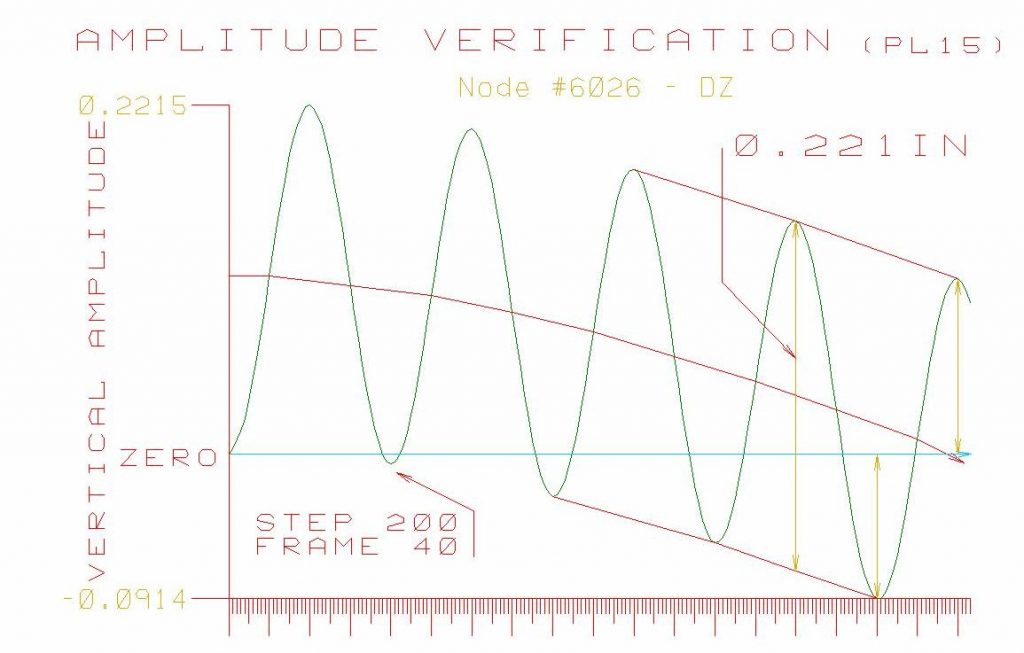

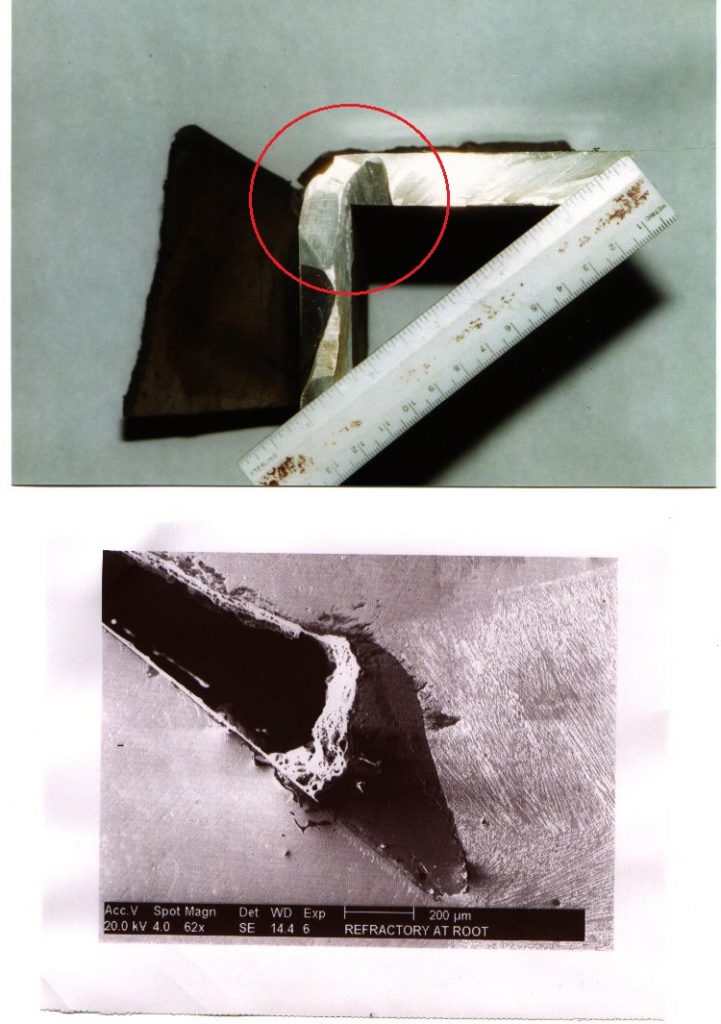

An elevator within a dairy processing facility was designed to convey material 16 feet vertically. The 12,000 lb and 8 foot diameter stainless steel weldment operated at 15 Hz (900 rpm) with a mass controlled forced vibration amplitude of 0.221 inches peak-to-peak vertically and 0.0042 radians peak-to-peak angular rotation. The forced motion was driven by counter rotating eccentric mass motors that applied cyclic forces on the order of 30,000 lbs. Fatigue cracks initiated at welds in several locations and propagated rapidly to the point of catastrophic failure. GES Tech Group was retained in 1996 to identify the root cause of failure. Field inspections, laboratory metallurgical analysis, and computer based non-linear dynamic time history analysis were applied during this investigation. Ultimately, fundamental design defects were identified that precluded the use of these vertical vibrating elevators in the dairy processing facility.

GES Tech Group was retained to represent the owner in legal proceedings that resulted from this equipment failure.