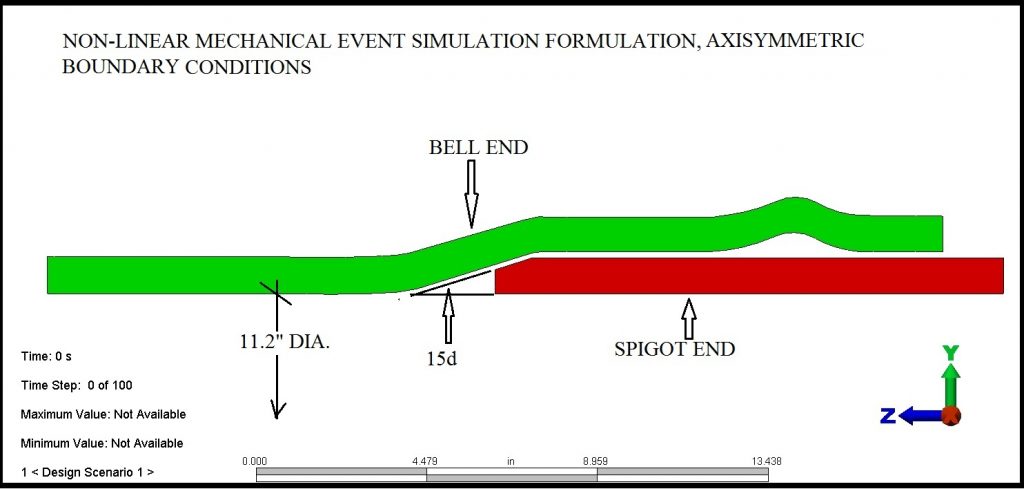

PVC material is routinely used in modern water delivery systems both in main lines and branch distribution networks. A typical connection design is termed “bell & spigot”, consisting of a spigot end that is inserted into a bell section, past a gasket to create a seal. The configuration allows for thermal expansion and contraction. Therefore, thrust blocks are required to react the resulting axial hydrostatic pressure forces.

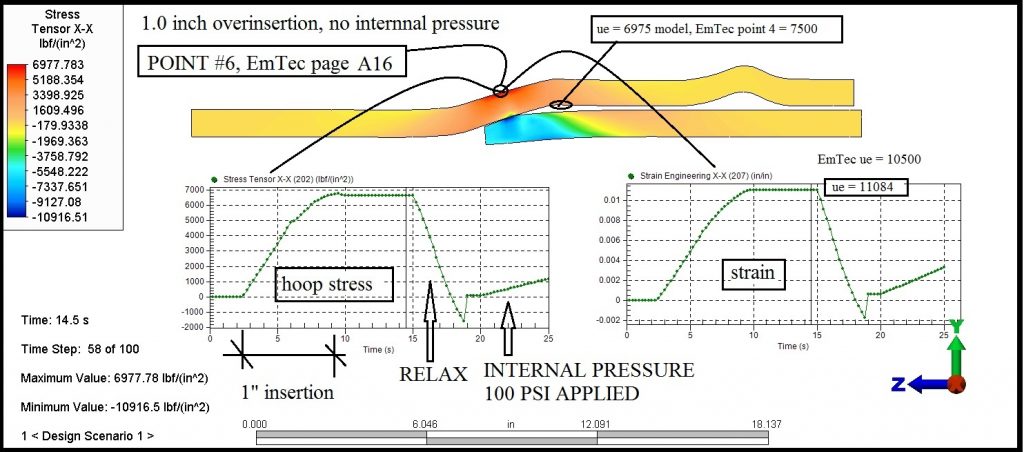

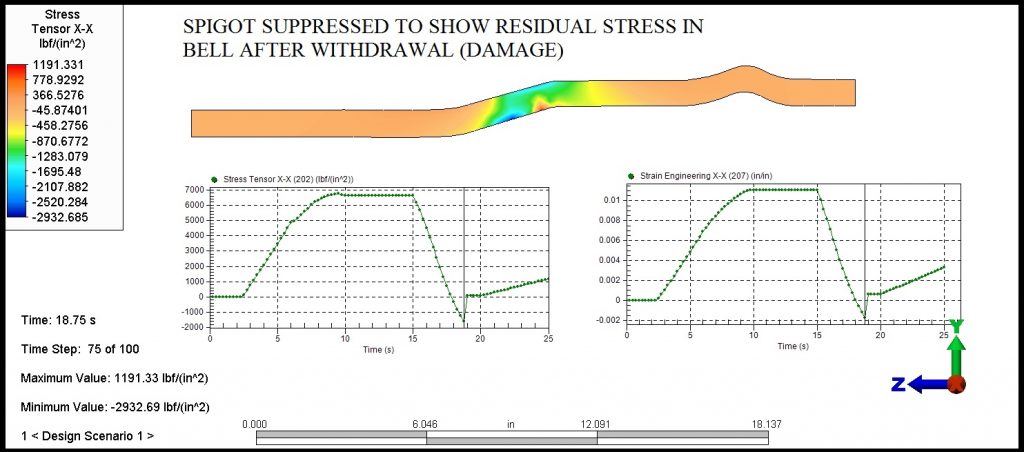

Over insertion of the spigot within the bell section during installation is a potentially serious issue due to stresses induced in the bell section and also the greatly reduced allowance for axial misalignment due to soil settlement or other installation issues.

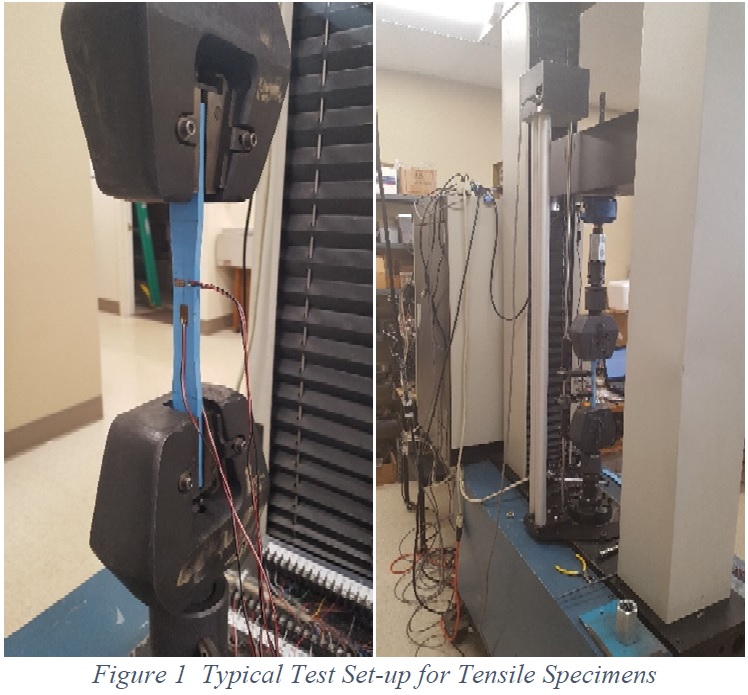

In 2017, GES Tech Group investigated the failure of a pipeline due to over insertion and axial misalignment. Laboratory testing provided actual mechanical property data for the viscoelastic PVC material and advanced non-linear finite element simulation was applied to characterize the physical results of over insertion. GES Tech Group findings in his matter were used in legal proceedings that resulted from this failure.