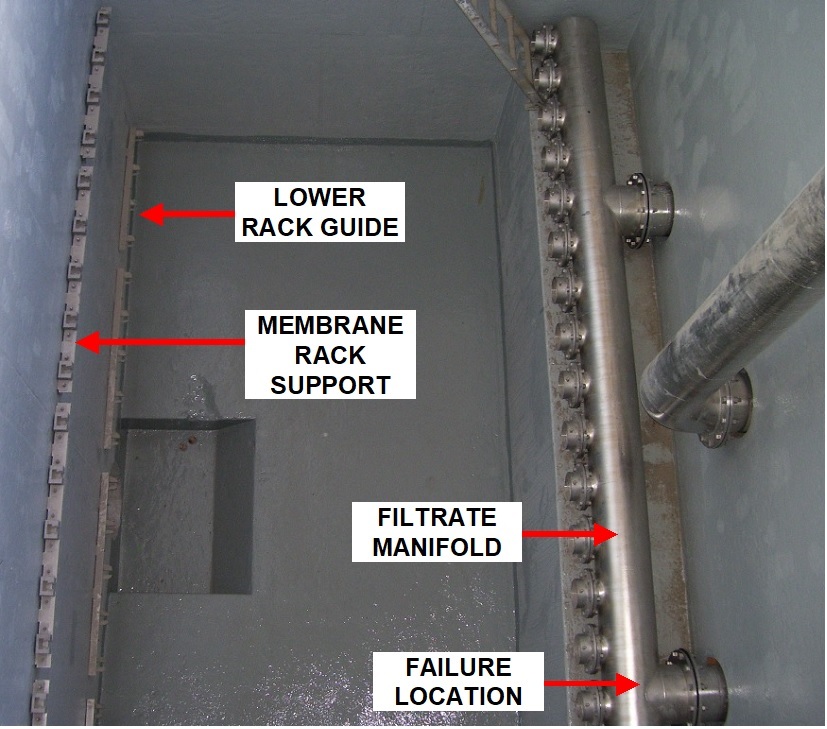

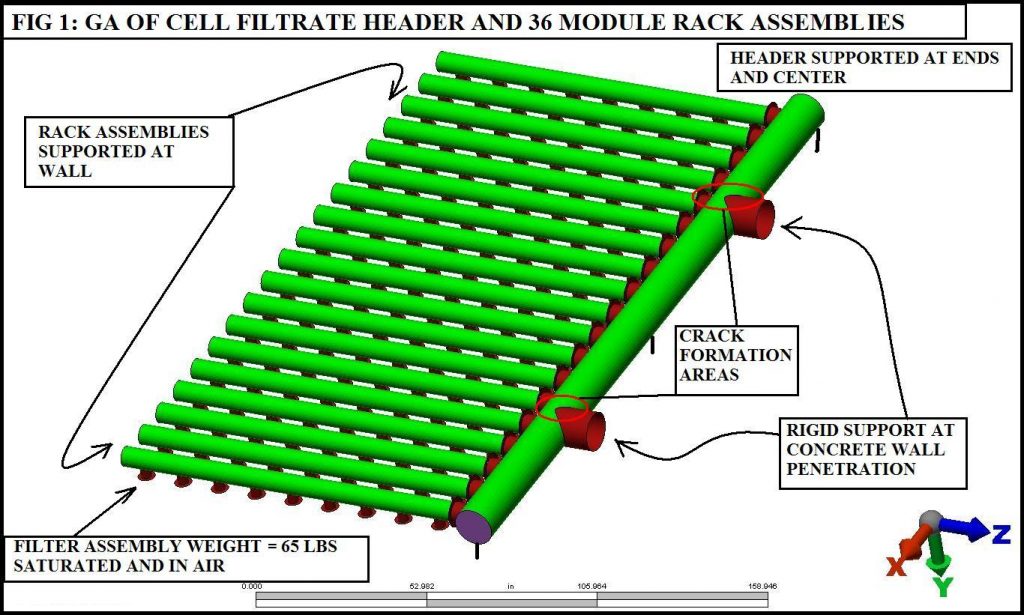

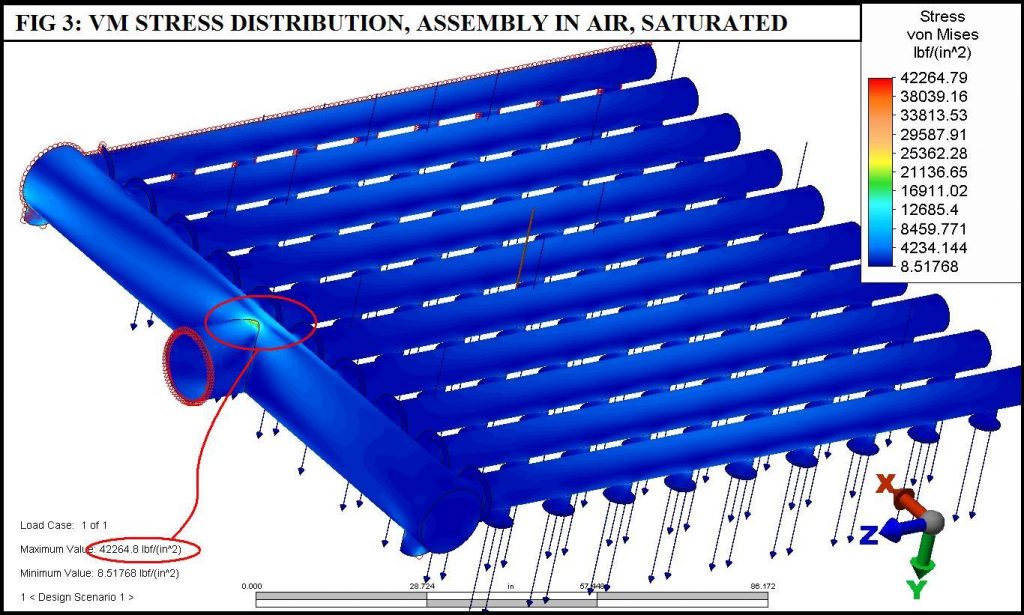

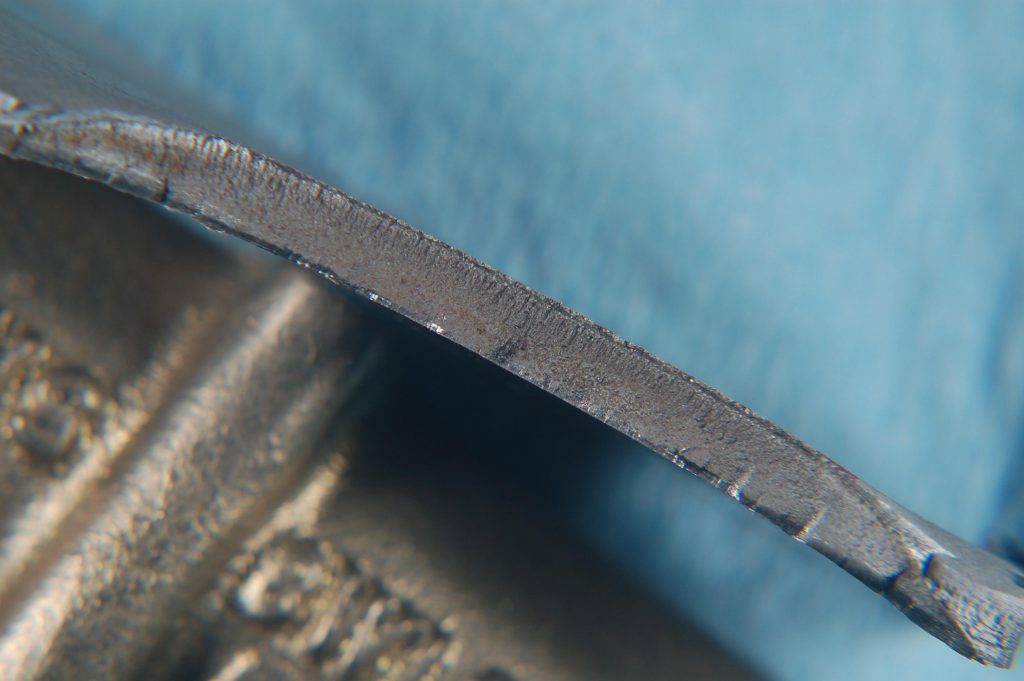

A stainless steel header system for a large MF/UF Membrain Filtration System in Southern California developed a series of cracks while in operation. Repeated efforts to repair the crack were not successful, with cracks appearing again soon after repairs. In 2015, GES Tech Group was retained to investigate and ultimately identified the root cause as fatigue crack initiation and propagation due to poorly designed supports and weld induced stress concentration factors. A modified support system was recommended and implemented to address the issue. GES Tech Group subsequently was retained to represent the vendor in discussions with the owner and the owners consulting engineers.