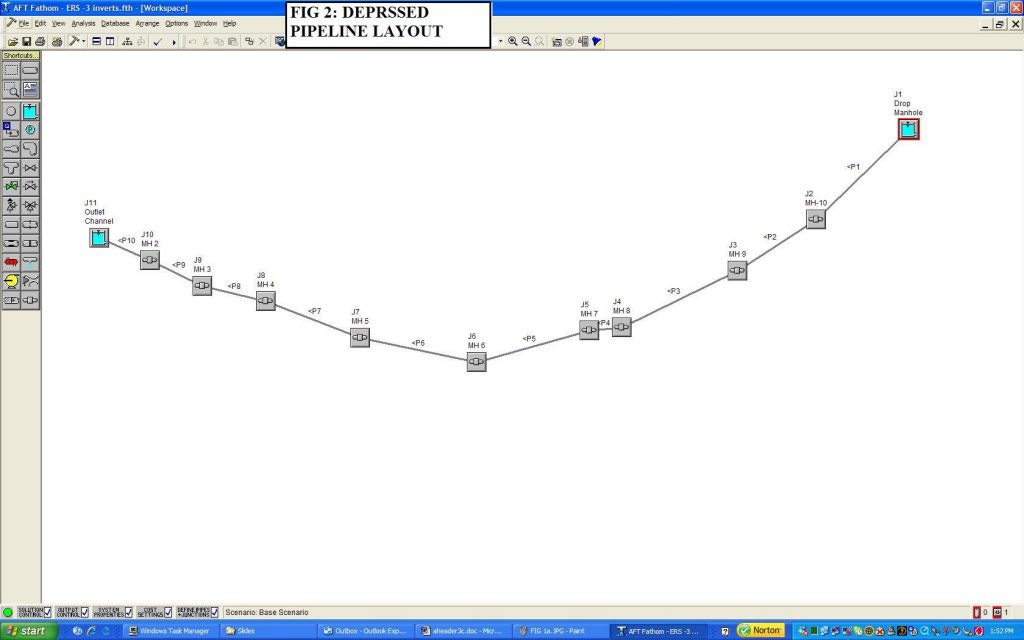

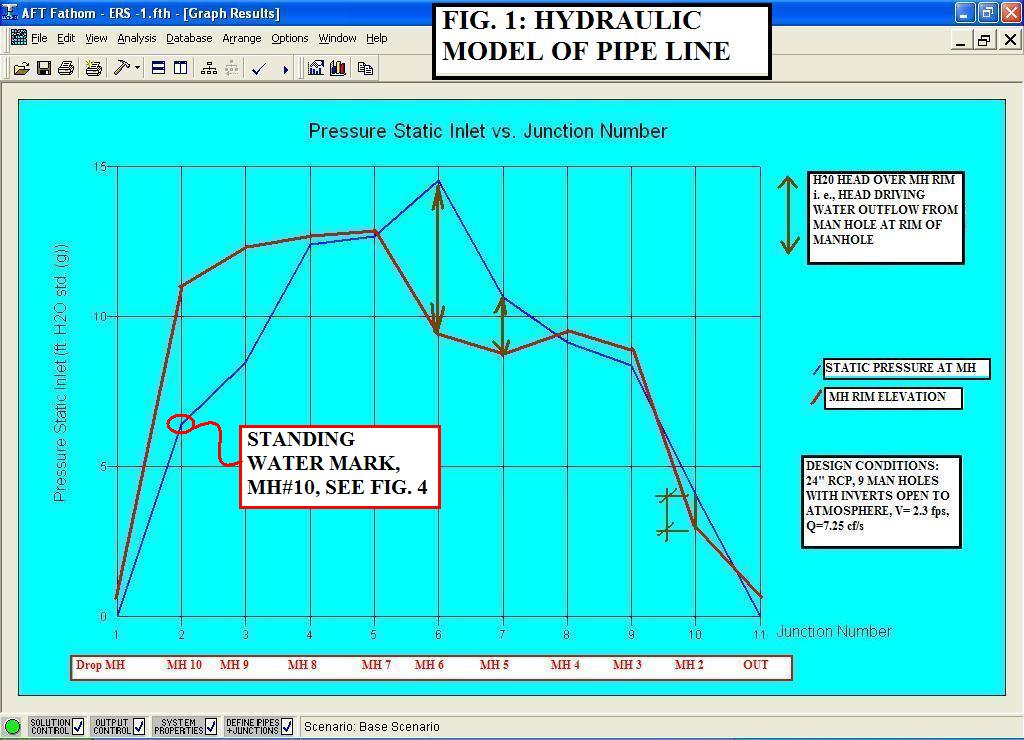

A subdivision in a Colorado town was built on the site of an existing irrigation ditch. The developer was therefore required to place the previous open channel ditch in a buried pipe within the newly constructed subdivision. The engineer-of-record on behalf of the owner replaced the existing open channel with an “inverted siphon” force main (i.e., under pressure). The design was, however, assumed to be an open channel with manholes along the path of the pipeline that were open to atmosphere. The manhole casings routinely filled to various elevations dependent on the hydraulic gradient. Several manhole covers were below the hydraulic gradient profile and thus under pressure and subject to leakage. In order to address the design error, the engineer-of-record directed the contractor to bolt the manhole covers to the casings with gasket material and sealant. Persistent surface leakage at manhole covers was the direct result along with damage to the casings due to internal hydraulic pressure.

Treating the symptoms only by bolting the manhole covers down and sealing with gaskets proved to be ineffective. GES Tech Group was retained in 2007 by the pipeline subcontractor to investigate the root cause of the failure and recommend solutions. GES Tech Group also represented the pipeline subcontractor in legal proceedings that resulted from the original defective design.