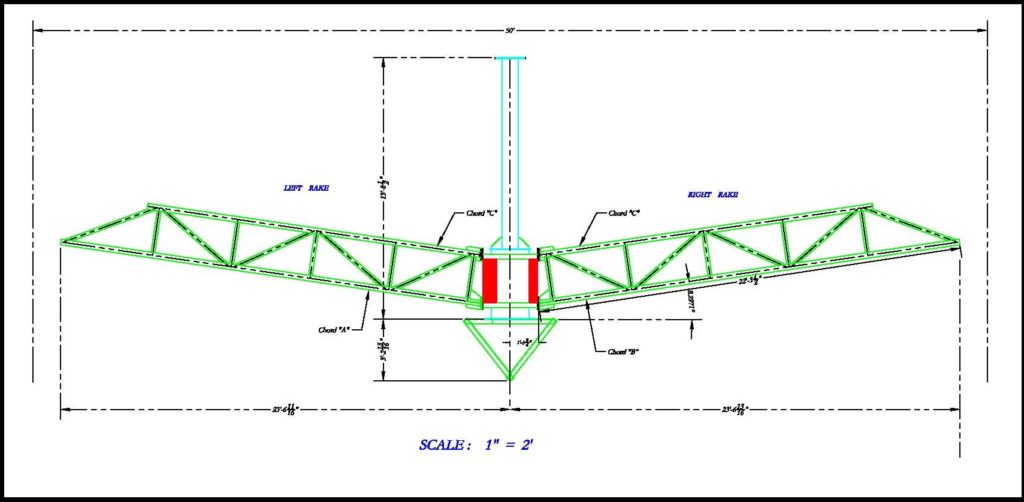

In 2002, a large USA mining firm required a 50 foot diameter replacement thickener rake arm assembly designed specifically for a severe high temperature acid environment. GES Tech Group was retained to conduct material corrosion testing and recommend materials resistant to the slurry.

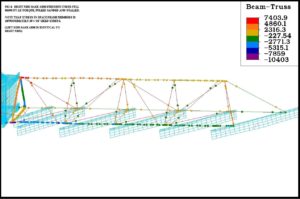

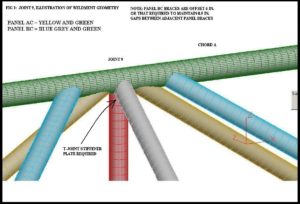

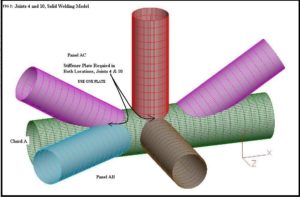

Rake arm section types, connections, and welding specifications were also critical to the design. GES performed detailed computer analysis of the applied operational, lift and upset loading conditions.

Design criteria included a center hub assembly able to effectively transmit 60,000 ft-lbs of torque and rake arm space frames fabricated only from pipe shapes (HSS) and plates due to availability of the recommended corrosion resistant material.